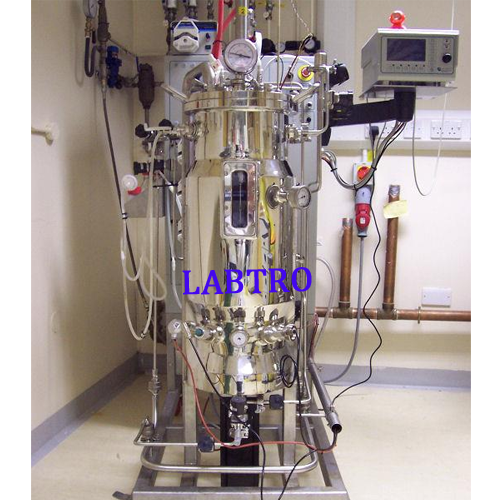

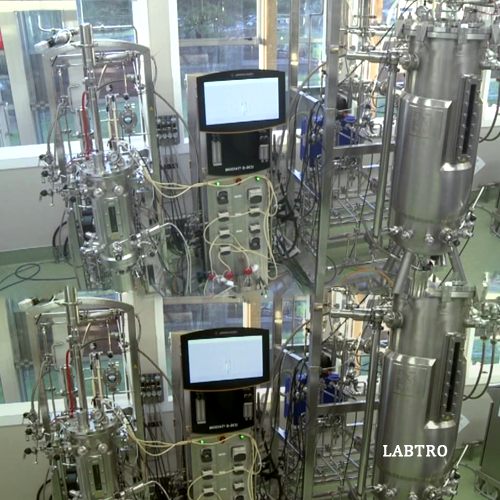

Labtro Laboratory Bioreactor Fermentor manufacturer and supplier exporter fermentor capacity 30 to 90 litres total volume.

Labtro Bioreactor Fementor sterilization is provided with the triple safety features. Labtro Bioreactor fermentor sterilization system which automatically limits the pressure to the required set valve and a spring loaded safety valve in case of its failure which releases the steam to keep pressure within the safety limits. Labtro Bioreactor Fermentor chamber design spring loaded safety valve and a dead weight release valve to release the steam in case the pressure exceeds the safety limit.

Labtro Bioreactor Fermentor controller features plug screen prevents the discharge line form choking. Labtro Bioreactor Fermentor electronic plug is easily removable for daily cleaning. Labtro Bioreactor sterilization system for drying sterilized cycle line circulates the air throughout the chamber.

- Labtro Bioreactor Fermentor motor gives maximum thrust of 920gms and weighs only 53gms.It is best suited for medium and large Labtro rotor shaft is made up of hardened steel and supported by sealed dual bearings. It comes with propeller mount with 5mm diameter. Powerful/ Accurate brushless motor, from 60 to 1350 RPM.

- Labtro Bioreactor Fermentor Illuminated side glass

- Imported sensors

- thermal Mass Flow Controller in entry model

- Automatic gas mixing

- Toro and sintered spargers

The software is the user’s best friend in experimental design planning and performing trial runs, as well as analyzing and optimizing media and parameters for cultivation.

The graphical user interface enables you to select the software functions intuitively. Data extracted are compatible with Windows Excel. However, Solaris has developed Leonardo data viewer, a platform where to easily and quickly manage fermentation data.

The software is included in the fermenter supply and can be installed on unlimited number of client’s PC or laptop.

- Choice between electro or steam heating for operation and sterilization; cost-effective integration into existing infrastructure

- Powerful DCU automation platform with newly added functions, e.g. Advanced DO controller, gravimetric feed control and up to four mass flow controllers allowing more sophisticated gassing strategies

- Safe to use due to maintenance-free agitator motor and automatic sequences for sterilization and pressure hold test

- Compact, mobile design saves valuable laboratory space.